Product Description

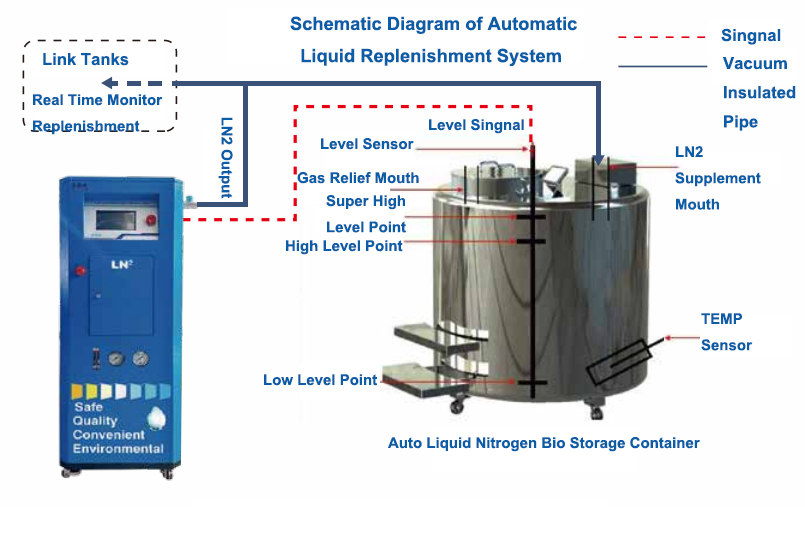

The liquid nitrogen generator (liquid nitrogen machine) consists ofthree parts: a nitrogen generator (internal orexternal), a refrigeration equipment (gas liquefaction equipment), and a Dewar tank, The whole machine has aone-click automatic liguid replenishment function, and the equipment automatically starts when the liquidnitrogen in the liquid nitrogen tank is below the set liquid level. The manufacturing of liquid nitrogen machineadopts the principle of mixed working fluid throttling refrigeration, which gradually cools nitrogen from theambient temperature to the saturation condensation temperature ofnitrogen liquefaction. The lowest coolingtemperature ofthe refrigeration mechanism can reach -196 'c, and the liquefed liquid nitrogen in therefrigeration evaporator is transported to the liguid nitrogen tank for storage to obtain liquid nitrogen. Theequipment automatically detects the liquid nitrogen level in the Dewar tank

Specification

| Model | ZPX-LN10L-H | ZPX-LN25L-H | ZPX-LN50L-H | ZPX-LN80L-H | ZPX-LN240L-H | ZPX-LN120L-H |

| Working power supply | AC220V 50HZ |

AC220V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

| Liquid nitrogen output /day |

8-10L | 15-25L | 30-50L | 60-80L | 100-240L | 120L-500L |

| mixtures refrigeration compressor | SECOP | Franch Tecumseh cryogenic compressor | Franch Tecumseh cryogenic compressor | German Bock semi-enclosed refrigeration compressor | German Bock semi-enclosed refrigeration compressor | German Bock semi-enclosed refrigeration compressor |

| Refrigerator power consumption | 1.2KW | 1.5KW | 2.5KW | 3KW | 3.5KW-4.5KW | 3.5KW-4.5KW |

| Nitrogen generator | built-in (Hollow fiber membrane) |

built-in (Hollow fiber membrane) |

built-in (Hollow fiber membrane) |

built-in (Hollow fiber membrane) |

built-in (Hollow fiber membrane) |

built-in (Hollow fiber membrane) |

| Nitrogen purity | >99.9% dew point temperature<-70 ° C, Nitrogen pressure>6Bar | |||||

| Power consumption of air compressor form | 0.55KW Piston oil-free type 0.55KW | 0.75KW Piston oil-free type 0.75KW | Piston oil-free type (frequency conversion)1.5KW | Mediation oil-free (frequency frequency)2.2KW | Mediation oil-free (frequency frequency)3.5KW | Mediation oil-free (frequency frequency)5KW |

| Installation method of air compressor | Internal/External | |||||

| automaticity | Automatic fluid replenishment | Automatic fluid replenishment | Automatic fluid replenishment | Automatic fluid replenishment | Automatic fluid replenishment | Automatic fluid replenishment |

| Noise level | < 55d b | < 55d b | < 65d b | < 65d b | < 65d b | < 65d b |

| Cooling method | Air cooling/water cooling | Air cooling/water cooling | Air cooling/water cooling | Air cooling/water cooling | water cooling | water cooling |

| Built-in dewar | 10L | 25L | 50L | 100L | 300L | 500L |

| Nitrogen output pressure | 0.5-1.5bar adjustable |

0.5-1.5bar adjustable |

0.5-1.5bar adjustable |

0.5-1.5bar adjustable |

0.5-1.5bar adjustable |

0.5-1.5bar adjustable |

| Liquid level display method | Capacitive liquid nitrogen level sensor | Capacitive liquid nitrogen level sensor | Capacitive liquid nitrogen level sensor | Capacitive liquid nitrogen level sensor | Capacitive liquid nitrogen level sensor | Capacitive liquid nitrogen level sensor |

| Touch Screen | Fully automatic control system | |||||

| Footing method | Fuma wheel (universal wheel) | |||||

| Size(mm) | 1200*450*550 | 1700*600*800 | 1700*1200*900 | 1700*1400*1000 | 1700*1600*1000 | 1700*2000*1200 |

| Weight(kg) | 100 | 150 | 220 | 350 | 460 | 550 |

The Use of Liquid Nitrogen

Industrial useFrozen and transported food

Thermophysical research

Refrigerant

Chemical testing

Low temperature protection for detector probes

Surgical Cryosurgery

Biological sample suturing and preservation of living tissue

University laboratories

Product advantages

-

The liquefaction system adopts advanced environmentally friendly mixed refrigerants (MR).

-

Refrigerator does not require regular maintenance, high reliability, and long service life.

-

All cryogenic fittings are insulated with vacuum to reduce cooling loss.

-

One-click touch screen, with a simple and easy to operate color Chinese and English interface.

-

The equipment has an automatic fluid replenishment function and a fully automatic control system.

Products

Products