Description

The 200 liter liquid nitrogen tank utilizes a small amount of liquid nitrogen vaporized in the tank to produce pressure, so that the tank can automatically discharge liquid nitrogen, thereby supplementing other liquid nitorgen containers, dewars, and cylinders with liquid nitrogen.

It is mainly used for transportation and storage of liquid media , and can also be used as a cold source for other refrigeration devices.

There are different size, such as 100 liter, 150 liter, 200 liter, 240 liter, 300 liter, 500 liter..... to meet different requirement.

Specification

| Model | Geometric volume | Effective volume | Dimensions | Empty weight | Full weight | Working pressure | Daily Steam Loss Rate | Infusion volume | |

|---|---|---|---|---|---|---|---|---|---|

| OD(mm) | Height(mm) | ||||||||

| YDZ-15 | 16.5 | 15 | 355 | 750 | 21 | 28.5 | ≤0.1Mpa | 7% | ≥2L/Min |

| YDZ-30 | 31.5 | 30 | 405 | 1050 | 32 | 56 | ≤0.1Mpa | 2.70% | ≥2L/Min |

| YDZ-50 | 55 | 50 | 455 | 1140 | 40 | 81 | ≤0.1Mpa | 2.20% | ≥4L/Min |

| YDZ-100 | 110 | 100 | 706 | 1180 | 69 | 150 | ≤0.1Mpa | 1.30% | ≥6L/Min |

| YDZ-150 | 160 | 150 | 606 | 1200 | 88 | 208 | ≤0.1Mpa | 1.20% | ≥8L/Min |

| YDZ-175 | 180 | 175 | 706 | 1260 | 98 | 238 | ≤0.1Mpa | 1.10% | ≥8L/Min |

| YDZ-200 | 210 | 200 | 706 | 1350 | 105 | 265 | ≤0.1Mpa | 1.10% | ≥8L/Min |

| YDZ-240 | 252 | 240 | 706 | 1480 | 115 | 307 | ≤0.1Mpa | 1.10% | ≥8L/Min |

| YDZ-300 | 313 | 300 | 806 | 1650 | 128 | 368 | ≤0.1Mpa | 1.10% | ≥10L/Min |

| YDZ-500 | 520 | 500 | 1108 | 1720 | 285 | 685 | ≤0.1Mpa | 1.10% | ≥12L/Min |

| YDZ-800 | 830 | 800 | 1310 | 1750 | 335 | 990 | ≤0.1Mpa | 1.10% | ≥15L/Min |

| YDZ-1000 | 1050 | 1000 | 1410 | 1920 | 375 | 1170 | ≤0.1Mpa | 1.10% | ≥20L/Min |

| YDZ-200W | 210 | 200 | 1480*706 | 840 | 110 | 270 | ≤0.1Mpa | 1.70% | ≥6L/Min |

| YDZ-300W | 315 | 300 | 1680*706 | 840 | 195 | 435 | ≤0.1Mpa | 1.50% | ≥8L/Min |

| YDZ-500W | 520 | 500 | 1750*1108 | 1250 | 290 | 690 | ≤0.1Mpa | 1.30% | ≥12L/Min |

| YDZ-950W | 1000 | 950 | 2100*1500 | 1560 | 355 | 1120 | ≤0.1Mpa | 1.30% | ≥20L/Min |

Feature

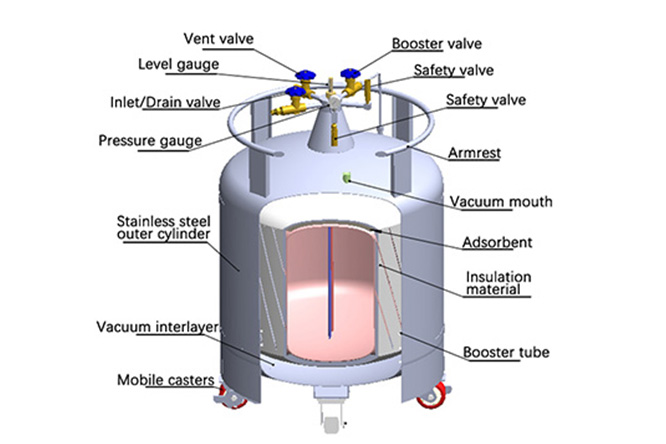

- Liquid valve (inlet/drain): When filling the container through the inlet/drain valve, first open the vent valve, connect the metal hose for infusion to the inlet/drain valve, and open the Inlet/drain Valve. That is, you can add liquid media through the inlet/drain valve. After filling, close the inlet/drain valve.

- Liquid level gauge: By observing the yellow indicator ring in the transparent display, the changes can be directly read in the liquid level.

- Storage: When you use this container to store liquid nitrogen, please close the inlet/drain valves and pressurization valves, and must open the vent valve.

- Transportation: When you use this container to transport liquid media, the opening and closing status of each valve should be the same as during storage. Please fix the container seat with the wheels under it, and use a rope to securely secure the container to the vehicle.

- Infusion: Close the vent valve, open the booster valve, and observe the pressure gauge. When the pressure rises to 0.05MPa (0.5kg/cm2), open the drain valve, which allows continuous infusion.

Application

- Low temperature treatment of metal materials.

The liquid nitrogen stored in the self-pressurized liquid nitrogen tank can undergo cryogenic treatment on metal materials, which can change the metal character of metal materials, significantly improving their hardness, strength, and wear resistance. - Deep cold assembly of precision parts.

After cryogenic treatment in a self pressurized liquid nitrogen tank, precision parts can be taken out for assembly, which can improve the assembly quality and sensitivity of precision parts, thereby improving the overall performance of equipment or instruments.

Products

Products